Caster is an important accessory of the carrier, most of the carrier is either hand-held or dragged, you in the choice of casters, should be based on the use of equipment and the use of environmental specifics, to choose the corresponding casters.

First of all, when you choose casters, you have to consider what kind of floor you are using the scene? Is it concrete or marble? Is the floor soft or hard? Do you need a high degree of protection for the floor?

Depending on the usage scenario, we recommend nylon or high strength polyurethane (TPU) for general concrete floors, and rubber wheels or cast polyurethane (PU) for indoor marble or wood floors.

Changing the wheel surface material of your casters will allow you to maximize their usefulness.

Second. What is the weight capacity and speed of the application? The faster you move, the more weight capacity the casters need. Caster diameter, width and material all affect the amount of weight a caster can carry at high or low speeds.

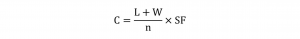

To determine the load capacity required for each caster on a cart, divide the maximum cart load by the number of casters. Then multiply this result by a safety factor that depends on the application conditions.

C = Required load capacity of casters

L = Maximum cart load

W = Cart weight

n = number of casters used

SF = Safety Factor

Indoor manual transportation = 1.35 (less than 3 mph)

Outdoor manual transportation = 1.8 (less than 3 mph)

Indoor power-driven transportation = 2 (less than 3 mph)

Outdoor power-driven transportation = 3 (less than 3 mph)

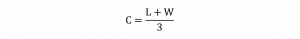

The following is a simpler form of this equation for a standard 4-caster cart with 2 universal and 2 directional casters, with even weight distribution on each wheel under indoor manual transportation conditions:

C = Required load capacity on casters

L = Maximum trolley load

W = Cart weight

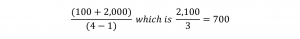

For example, consider a 300 lb cart with a 1,800 lb load on it. This would be 2,100 lbs. divided by 3. For this load, each caster must support/be rated for 700 lbs. or more.

Other factors should be evaluated to specify the exact caster needed for the application, such as: caster configuration, ambient temperature, duty cycle, tread material, and speed (wheels with ball bearings will have a reduced load capacity at speeds over 3 mph).

As always, our solutions specialists can discuss your application to ensure that the correct caster is used, as casters are more than just wheels.

Third, what is the temperature of the environment where it is used? Are the casters used indoors or outdoors? In actual use, both high and low temperatures will affect the operation of the caster to some extent.

Fourth, what are the unique conditions and environments in which your casters will be used? Is there debris? Is there moisture or harmful chemicals? Will the sun constantly beat down on your casters? Will static electricity conduct to the casters and damage valuable products?

All of these questions and more need to enter into the decision-making process.

If you have more questions about caster selection, feel free to contact us privately.

Post time: Nov-13-2023