As a common mechanical component, industrial universal wheel is widely used in transportation equipment in various fields. When purchasing industrial universal wheel, it is crucial to choose the right product as it is directly related to the stability, operability and life of the equipment. Today, I will introduce you some considerations and concerns from a purchaser’s perspective to help you make an informed decision when purchasing industrial universal wheels.

1. Load capacity: the first thing to consider is the load capacity of the industrial universal wheel. Select the appropriate load capacity according to the needs of your equipment and the environment in which it will be used. Make sure that the rated load of the selected product can meet your needs, and have a certain margin to cope with unexpected situations and overload.

2. Wheel surface material quality: The material quality of industrial universal wheel directly determines its service life and durability. Usually, materials such as nylon and polyurethane are widely used in the manufacture of industrial universal wheels. According to the working environment of your equipment, choose the suitable material to ensure that it can resist adverse conditions such as corrosion, abrasion and high temperature.

3. Ground Adaptability: The ground adaptability of industrial casters is also an important consideration. According to the required mobility of your equipment and the environment in which it is used, choose the appropriate tire material and design. For example, rubber tires are suitable for indoor floors, while polyurethane tires are better suited for use on uneven surfaces.

4. Steering performance: The steering performance of an industrial universal wheel is critical to the handling and maneuverability of the equipment. Ensure that you choose a universal wheel with flexible steering capabilities so that the equipment can be easily steered, turned and positioned. In addition, pay attention to the wheel’s steering radius and anti-sway performance to ensure the stability and safety of the equipment.

5. Braking and securing features: Depending on the needs of your equipment, consider whether you need industrial casters to have braking and securing features. Braking systems provide additional safety by preventing equipment from sliding or rolling when stopped. Fixed features can lock the wheel to ensure that the equipment does not move when it needs to be in a fixed position.

6. Noise and vibration: When choosing an industrial universal wheel, it is also necessary to understand its noise and vibration characteristics. Some high-quality universal wheels use shock-absorbing design and noise-reducing technology, which can reduce the noise and vibration level when the equipment is running, and enhance the comfort of the working environment.

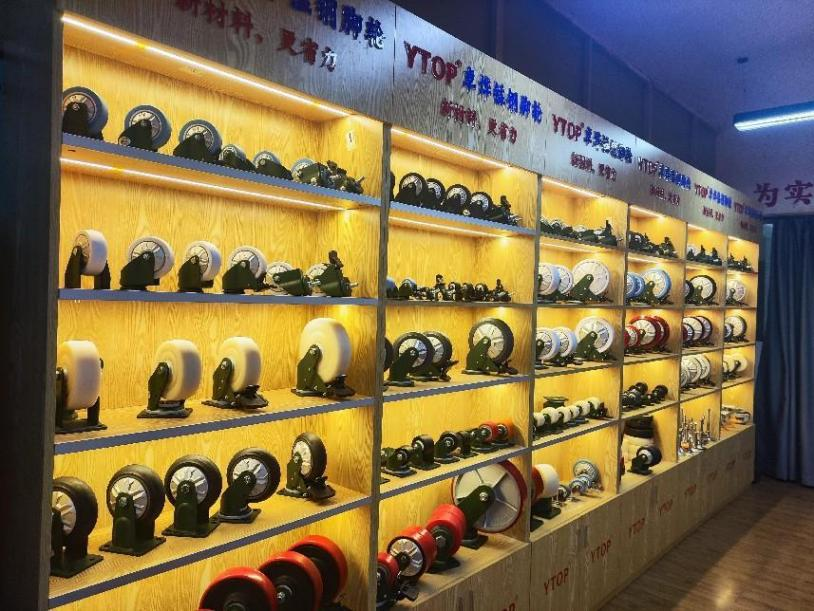

7. Brand and supplier reputation: Finally, choosing a well-known brand and reliable supplier is also an important factor. Well-known brands usually have rich experience and technical strength to provide reliable quality industrial casters. Meanwhile, establishing cooperative relationship with reliable suppliers can get better after-sale service and technical support. In terms of quality, Zhuo Ye manganese steel casters promise a two-year warranty, which is the commitment of a big brand.

Conclusion:

When purchasing industrial universal wheels, it is necessary to comprehensively consider factors such as load capacity, material quality, ground adaptability, steering performance, braking and fixing function, noise and vibration. Choosing the right industrial universal wheel can enhance the performance and reliability of your equipment and extend its service life. By focusing on the key points and following the above recommendations, you can make informed purchasing decisions and select high-quality industrial casters for your equipment.

Post time: Dec-29-2023