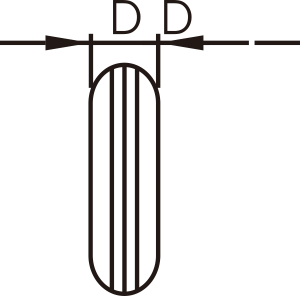

The width of a caster has a significant effect on its performance, the This is mainly reflected in the following areas:

Grip and stability

Wider casters have a larger contact area, the This usually means more grip and greater stability.When lifting heavy objects or moving over uneven surfaces.This characteristic is particularly important.This is because it helps prevent slipping and tipping.

Maneuverability and speed

In comparison.Narrower casters, due to the small contact area of the May provide faster acceleration and higher maneuverability.This makes them suitable for application scenarios that require quick turns or maneuvering in tight spaces.

Weight and energy consumption

Wide casters due to the large contact area may increase rolling resistance.Causes more energy to be needed when moving.And narrow casters, due to their small contact area, the Lower rolling resistance.Therefore it may be more energy efficient under the same conditions.

durability

The width of the caster may also affect its durability.Wide casters may be better for spreading the load.Reducing pressure on individual contact points.This extends the service life.Narrow casters, on the other hand, may be more prone to wear when subjected to uneven loads.

application scenario

Casters of different widths are suitable for different working environments and transportation needs.For example.Wide casters may be chosen for warehouse trucks to improve stability, the Whereas, a hand cart or tool cart may opt for narrow casters for improved maneuverability and speed.

In summary.Choosing the right width of caster depends on the requirements of the particular application.This includes factors such as load size, ground conditions, speed of movement and ease of operation.

Post time: Jun-28-2025