Casters are one of the indispensable transportation equipment in the fields of logistics, warehousing and transportation. In order to improve the efficiency and convenience of transportation, the design of casters becomes more and more important.

The design of casters directly affects their performance and usage experience. Good caster design can provide better comfort, stability and efficiency while reducing noise and wear. Conversely, poor design can lead to breakdowns, reduced equipment life and increased transportation costs.

I. Caster design concept

Weight Reduction

The primary goal of caster design is to reduce the weight of the equipment itself, thereby improving handling efficiency. Weight reduction can be achieved through the use of lightweight materials, optimize the structure and reduce unnecessary components.

Improving Efficiency

Improving efficiency is another important goal in caster design. To increase efficiency, the size and rotational properties of the caster can be optimized for smoother operation with less friction and energy loss.

Improving Comfort

Improving operator comfort is another key factor in caster design. Comfort can be achieved by optimizing the elasticity of the caster, reducing noise and minimizing vibration.

Durability and reliability

Casters need to withstand a variety of environmental and transportation conditions, so durability and reliability are key design factors. The design should take into account the durability of the materials and structure to ensure that the caster maintains its performance over a long period of time.

Steps in caster design

Demand analysis

Before designing a caster, it is important to first understand the customer’s needs and usage scenarios. Demand analysis helps to determine the basic functions and performance requirements of casters.

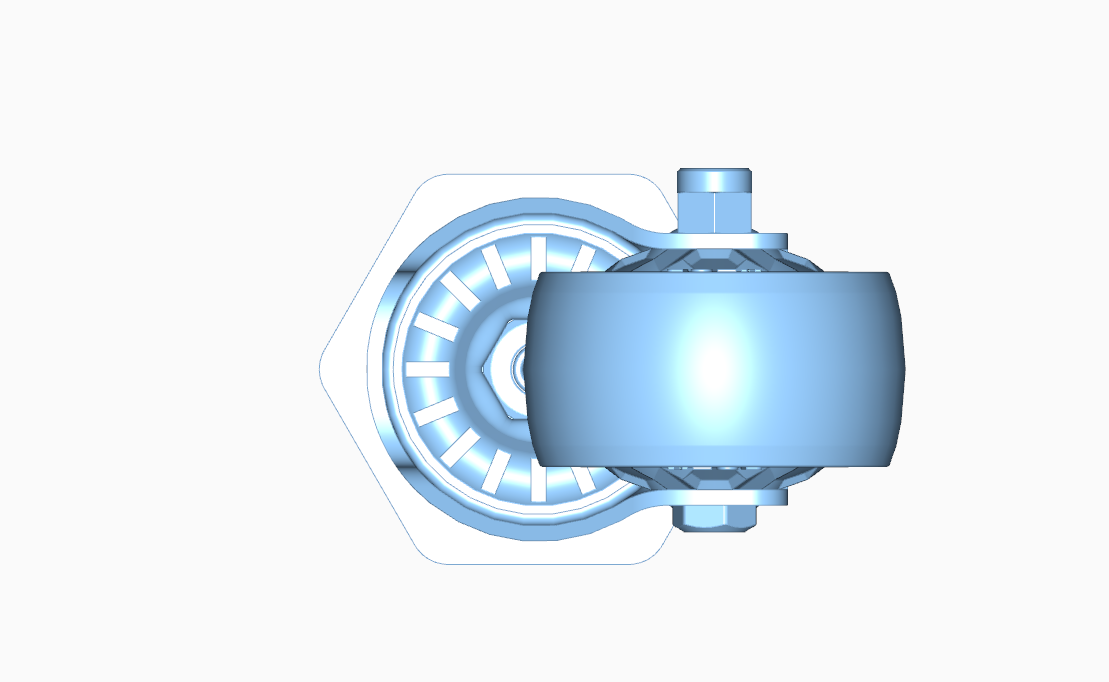

Structural Design

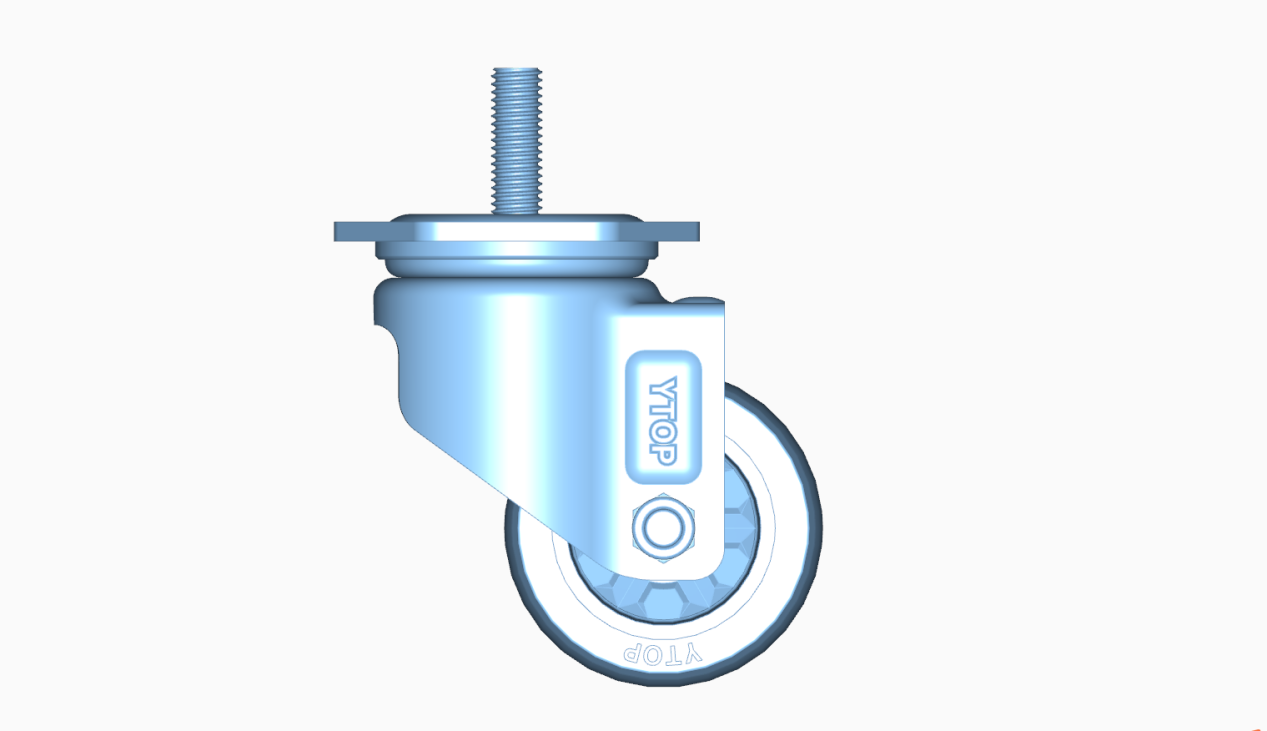

After understanding the requirements, structural design can be carried out. Structural design includes determining key parameters such as caster size, number of wheels, wheel diameter and bearings. In addition, the matching of the casters to the equipment and the mounting method need to be considered.

Material Selection

The choice of material has an important impact on the performance and service life of casters. Suitable materials, such as wheel materials, bearings and tires, should be selected according to the needs and conditions of use.

Manufacturing

After completing the structure and material selection, manufacturing can start. The manufacturing process should ensure the quality and performance of the caster while controlling the cost.

Testing and Optimization

The final step is to test and optimize the caster. Testing should include evaluating the performance, comfort and durability of the caster in a real-world environment. Based on the test results, necessary optimizations and improvements are made to improve the performance and user experience of the caster.

Application Cases

Logistics Warehouse

In logistics warehouses, the design of casters plays a key role in the efficiency and quality of goods transportation. For example, a logistics company uses casters with high load-bearing capacity and excellent rotation performance, which greatly improves the speed and accuracy of cargo handling and reduces transportation costs.

Medical Equipment

The design of casters for medical equipment takes into account factors such as the weight of the equipment, smoothness of movement and noise. For example, a medical equipment manufacturer uses casters with high elasticity, low noise and anti-wear properties to ensure the stability and comfort of the equipment during movement.

Post time: Jan-12-2024