The performance of casters in extreme environments is influenced by a number of factors.Key Inclusions:

Temperature resistance of the material:In a hot environment.Caster materials need to be able to maintain the physical properties that Avoid deformation or performance degradation due to increased temperature.Commonly used high-temperature resistant materials include heat-resistant alloys, silicone rubber, and ceramic materials.

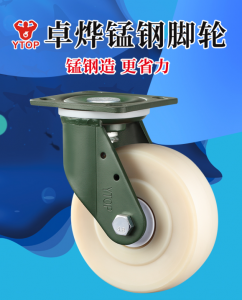

Structural design:The design of casters must take into account the effects of high-temperature environments on materials and construction.Ensuring adequate thermal stability and load-bearing capacity.To prevent fracture or deformation under the combination of high temperatures and heavy loads.

Environmental Adaptation:Casters need to be dust, corrosion and abrasion resistant.To ensure performance stability and longevity in environments such as dusty, chemically treated or humid environments.

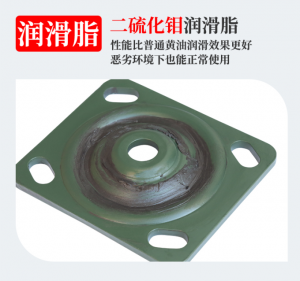

Bearings and lubrication:In a high-temperature environment, the Conventional lubricants may fail, the Therefore, the high temperature resistant caster adopts self-lubricating technology.By adding solid lubricants to the material or using surface coating techniques.to maintain good lubrication.

Thermally isolated structure:Adding a thermal barrier between the rollers of the casters and the bracket.It can effectively stop the transfer of heat that Protects the bearings and lubricants inside the caster from heat damage.

These factors combine to determine the reliability and durability of casters in extreme environments.It is a key point that must be comprehensively considered when designing and selecting heat-resistant casters.

Post time: May-23-2025