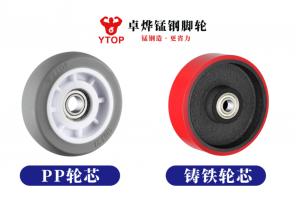

Iron core casters and PP core casters are two common types of casters.Their main difference in material is reflected in the center part of the caster.That is, the material of the wheel center.Iron core casters have a wheel center usually made of metal.Usually iron.PP core casters, on the other hand, have a wheel center made of polypropylene (Polypropylene, PP for short), a plastic material.

The following are specific differences between the two in terms of material:

Comparison Dimensions Iron core casters PP core casters

Material Metal (usually cast iron or aluminum) Polypropylene plastic

Weight Heavier, provides stability Lighter, easier to move

Load bearing capacity Higher, suitable for heavy-duty applications Moderate, suitable for non-heavy-duty applications

Impact resistance Good, due to the hardness of the metal Good, but lower than the metal

Abrasion resistance Higher, the metal is good, good for abrasion resistance Good, depending on the quality of the PP material Chemical resistance Fair, may be attacked by some chemicals Better, PP is resistant to most chemicals

Insulation Poor, metal conducts electricity Good, PP is a non-conductor

Cost Higher, metal processing and material costs Lower, plastic material costs are lower

Environmental suitability Suitable for high temperatures or harsh environments Suitable for general environments, but performance may deteriorate at high temperatures

Cast iron core casters, because of their metal.Typically providing higher load-bearing capacity and impact resistance, the Suitable for use in industrial environments, the Especially where heavy loads or frequent impacts are required.In comparison.PP core casters due to their plastic material.Lighter weight.Lower cost.Suitable for applications with low weight requirements and mild environments.Handling, non-heavy equipment . Iron core casters and PP casters are two common types of casters.They differ in material and construction.Therefore it is suitable for different usage scenarios.

Iron core casters usually consist of a center section made of metal and a rubber or other synthetic material wrapped around the outside.This structure makes the iron core casters have high load bearing capacity and wear resistance.Ideal for carrying heavier equipment and items.The metal portion of the iron core caster also provides a degree of rigidity and impact resistance.Make it suitable for rough or uneven floors.In addition.The metal of the iron core casters also makes them more electrically conductive.Suitable for environments where electrical conductivity is required.

PP casters.i.e. polypropylene casters.It is a lightweight caster made of polypropylene material.PP material has good chemical stability and corrosion resistance.and a low coefficient of friction.This makes PP casters suitable for clean environments or places where contamination needs to be avoided.They are typically used in electronic devices, medical devices or mobile equipment in the food processing industry.The lightweight nature of PP casters also makes them ideal for manual handling vehicles.Especially when frequent movement or handling of light cargo is required.

reach a verdict

Overall.Iron core casters, because of their high strength and abrasion resistance.Ideal for industrial environments where heavy loads need to be carried and where poor ground conditions prevail.PP casters, on the other hand, because of their lightweight and anti-pollution properties.Suitable for environments with high cleanliness requirements and manual handling operations.When selecting casters, the The decision to use iron core casters or PP casters should be made according to the specific conditions of use and requirements.

Post time: Jun-21-2025