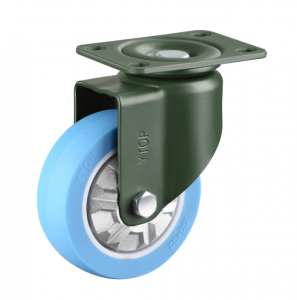

Casters,This seemingly simple yet powerful widget,It is ubiquitous in our daily lives.Whether it’s industrial machinery, medical equipment, or furniture,All of them rely on its assistance.The performance and durability of the casters,It largely depends on the materials used in its manufacture.Today,Let’s take a look at the applications of several common materials in casters.

First,Let’s talk about nylon materials.Nylon is a synthetic material characterized by high strength, high toughness, and excellent wear resistance.Therefore, it is widely favored in the manufacturing of casters.Nylon casters not only offer excellent load-bearing capacity,Moreover, it has a smooth surface.Low coefficient of friction,Significantly reduces noise and resistance during equipment operation.Additionally,Nylon materials also exhibit excellent corrosion resistance.Resistant to corrosion by alkalis, most salt solutions, and weak acids.Therefore, it can maintain stable performance even in certain special environments.

Next up is TPU material.TPU,Thermoplastic polyurethane elastomer,It is a polymer material characterized by wear resistance, oil resistance, and excellent elasticity.TPU casters not only offer excellent load-bearing capacity,And it can maintain stable performance in various harsh environments.However,It should be noted that,TPU materials exhibit relatively poor hydrolysis resistance.Therefore, care should be taken to avoid prolonged exposure to moisture during use.

Now let’s talk about rubber materials.Rubber casters are renowned for their high friction coefficient and excellent shock absorption properties.The rubber tread is soft and provides stable support.Simultaneously reduce vibration and noise during equipment operation.Additionally,Rubber materials also possess excellent heat dissipation properties.Can withstand higher speeds and longer operating times.However,Compared to nylon and TPU,Rubber exhibits relatively poor abrasion resistance and chemical resistance.Therefore, careful selection is required in certain specialized application scenarios.

In addition to these common materials,Metal materials are also an indispensable part of caster manufacturing.Metal material,especially steel and stainless steel,High strength and excellent load-bearing capacity,Suitable for heavy-duty applications and harsh environments.Aluminum alloys, however, are favored for their lightweight, corrosion-resistant, and easily machinable properties.It has found widespread application in scenarios where weight and aesthetic appeal are critical considerations.

Additionally,Plastic materials also constitute a major category in caster manufacturing.Plastic caster brackets feature lightweight construction, impact resistance, and corrosion resistance.Moreover, it comes in a wide variety of colors.Customization is available upon request.They are typically used in applications involving light and medium loads.such as homes, offices, etc.

Finally,We should also mention composite materials.Composite materials combine the advantages of multiple materials.Such as high strength, lightweight, corrosion resistance, etc.Therefore, it is widely used in special applications with high performance requirements.such as aerospace and medical devices.In the manufacturing of casters,The application of composite materials is also gradually increasing.Offers more possibilities for enhancing the performance of casters.

In summary,Different materials each have their own merits in casters.Selecting the appropriate materials not only enhances the performance and durability of casters,It can also meet the usage requirements for different occasions and needs.Therefore,When selecting casters,We need to select appropriate materials based on actual application scenarios and requirements.To ensure the stable operation and efficient performance of the equipment.

Post time: Sep-09-2025