Casters,This seemingly insignificant yet powerful component,Plays a pivotal role in daily life and work.Whether it’s the easy movement of home furnishings,or the handling of heavy objects in industrial production,Even shopping carts in malls and supermarkets,All of them rely on the assistance of casters.Today,We will delve into the underlying principles of caster structure.and explore the application characteristics of various casters, including flat-bottom, threaded-rod, and top-hole designs.

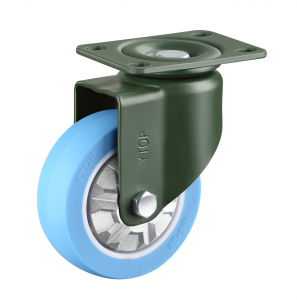

First,Let’s take a look at the basic structure of casters.Casters primarily consist of a hub, wheel, bearing, and bracket.The hub, as the core of the caster wheel,Connecting the wheels to the main body of the equipment;The wheel is the part that comes into direct contact with the ground.The material and diameter directly affect the caster’s load capacity and rolling resistance;The bearing is located between the hub and the wheel.Ensure the wheels rotate smoothly;The bracket serves to connect the casters to the main body of the equipment.Ensure stable installation and flexible adjustment of the casters.

Flat casters are one of the most common styles.Its characteristic is a flat bottom.Suitable for most level ground conditions.In home life,Flat casters are widely used on the bottom of furniture.such as bookshelves, dining tables, etc.allowing furniture to be easily moved,Easy to clean and rearrange.In the shopping experience,Flat casters also play an important role.Whether it’s a supermarket shopping cart or a suitcase,Flat casters make moving effortless.

Ball-screw casters represent another unique design.It features an adjustable lead screw mechanism.to accommodate varying heights and uneven ground conditions.Screw-type casters are particularly common in the handling of heavy equipment.Such as scaffolding and large equipment at construction sites.The screw mechanism allows for easy height adjustment of the casters.Ensure stability and safety even in complex terrain.

The defining feature of top-hole casters is the hole designed at their top.Easy to install and secure.This design has led to the widespread adoption of top-hole casters in industrial mobile equipment.For example,On industrial equipment such as forklifts, hand trucks, and shelving,Top-mounted casters play a crucial role.Forklifts must carry heavy loads and maintain stability.Top-hole casters can support the weight of forklifts and cargo.Ensure the stability and safety of the forklift.Hand trucks are also widely used in warehousing, logistics, and other fields.Top-mounted casters make the cart easier to move.Improved work efficiency.Shelving, as a vital component of warehouse facilities,Top-hole casters are used to support shelving units.Ensure the stability and load-bearing capacity of the shelves.

In addition to flat-bottom, threaded-rod, and top-hole casters,There are also threaded casters, elastic casters, and other styles.Threaded casters adjust height by rotating the threaded shaft.Suitable for scenarios requiring precise adjustments;Elastic casters are equipped with springs.It can reduce vibration and noise while enhancing movement stability.Particularly suitable for equipment requiring prolonged movement or vibration.

In summary,Though small, the casters,Yet its structure and applications embody profound scientific principles.Flat-bottomed, threaded-rod, top-hole, and other styles of casters,Each plays an irreplaceable role in their respective fields.Whether in home life or industrial production,Casters quietly provide us with convenience and support.With the advancement of technology and the ever-changing needs of people,The structure and application of casters will also continue to innovate and improve.Bringing more convenience and surprises to our lives.

Post time: Sep-04-2025