Casters.As an important part of the connection between the equipment and the ground Its carrying capacity is directly related to the stability, safety and service life of the equipment.in industrial production, logistics and transportation, medical equipment, furniture manufacturing and many other areas.The load carrying capacity of the casters are all key factors that cannot be ignored.In this article, we will discuss the determinants of the load-bearing capacity of casters from a number of aspects.and provides a practical guide when choosing casters.

I. Material

The material of the caster is one of the key factors in determining its load carrying capacity.Common caster materials include rubber, polyurethane, nylon and metal.Different materials have different physical properties and load-bearing capacity.Example:

Casters made of metal usually have high load-bearing capacity and durability.Suitable for heavy-duty applications.

Rubber or polyurethane casters have better elasticity and shock absorption properties.Suitable for applications where smoothness is important.

Nylon wheels have a low coefficient of friction and abrasion resistance.Suitable for different floors, both indoors and outdoors.And the load-bearing capacity is also higher.

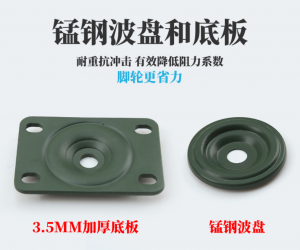

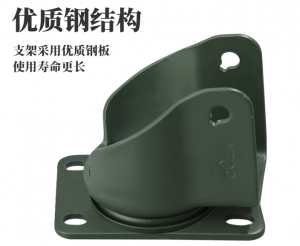

II. Structure

The structural design of the caster also has a significant impact on the load carrying capacity.Reasonable structural design can ensure that casters can evenly distribute pressure when bearing heavy loads.Avoid localized overloads.In addition.The accuracy and durability of key components such as bearings and axles of casters are also important factors affecting load-carrying capacity.High-quality bearings reduce friction and wear.Increase the load-bearing capacity and service life of casters.

III. Dimensions

The size of the caster is also an important factor in its load capacity.In general.Larger diameter casters offer better stability and load bearing capacity.Because they are able to spread out more pressure.Meanwhile.The width and thickness of the caster also affects its load-bearing properties.The wider wheel surface provides a better support area, the Increases the stability of the caster;While a thicker rim provides better impact resistance, the Increase the durability of casters.

IV. Environment of use

The environment in which the casters are used is also a non-negligible factor that affects their load-bearing capacity.Different environments require different materials, structures and performance of casters.Example:

Casters used in wet or corrosive environments need to have better corrosion resistance.

casters used in high or low temperature environments require better heat or cold resistance.

The flatness, hardness and coefficient of friction of the floor will also have an effect on the load capacity of the caster.When using casters on uneven ground, the carrying capacity may be reduced.This is because uneven ground increases tire wear and friction.

V. Other factors

In addition to the above factors.The load-bearing capacity of a caster may also be affected by other factors, the Such as manufacturing process, frequency of use and maintenance status.High-quality manufacturing processes ensure the precision and durability of the caster’s components.thereby increasing its carrying capacity.Whereas frequent use and lack of maintenance can lead to increased wear and tear on casters.Reduced carrying capacity.

In summary.The load carrying capacity of casters is determined by a number of factors such as material, structure, size, use of the environment and manufacturing process.When selecting and using casters, the The need to synthesize these factors.To ensure that the casters are able to meet the actual needs and challenges of the environment in which they are used.

Post time: May-24-2025