Casters,As an indispensable component in modern logistics and manufacturing,Widely used in the movement of various equipment, machinery, and furniture.Selecting the right casters not only enhances the mobility efficiency of equipment,It also ensures safety and stability during use.So,How to choose the right casters for your needs? This article will provide a detailed guide.

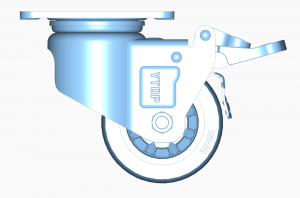

I. Understanding the Basic Components of Casters

Casters primarily consist of components such as the hub, bearing, spokes, and tire.Among these,The hub is the component connecting the caster to the equipment.The bearing determines the smoothness of the caster’s rotation.The rim supports the tire and transmits force.The tires make direct contact with the ground.Affects mobility and wear resistance.

II. Define Use Cases and Requirements

Before selecting casters,First, clearly define the usage scenarios and requirements.For example,Is it for indoor or outdoor use?What is the required load capacity?What are the requirements for movement speed?Factors such as ambient temperature and humidity must also be taken into account.

III. Selecting the Appropriate Material

The material of casters directly affects their load-bearing capacity, wear resistance, and service life.Common materials for casters include metal, plastic, and rubber.Metal casters offer high load-bearing capacity.However, it may not be suitable for use in damp or corrosive environments;Plastic casters are lightweight and corrosion-resistant.However, its load-bearing capacity is relatively weak;Rubber casters provide excellent shock absorption and noise reduction.

IV. Pay attention to dimensions and specifications

The size and specifications of casters are also important factors to consider when making a purchase.Different equipment and scenarios require casters of different sizes.To ensure stability and mobility.Additionally,Also note the installation method and interface type of the casters.To ensure compatibility with the device.

V. Consider Brand and Service

Choose casters from well-known brands.Typically signifies higher quality assurance and more comprehensive service.When purchasing,You can pay attention to aspects such as the brand’s reputation, customer reviews, and after-sales service.to ensure better support during subsequent use.

VI. Price Factors

Price is not the only factor determining the quality of casters,It is also an important reference indicator.When selecting,Don’t blindly pursue low prices.Instead, a comprehensive evaluation should be conducted based on factors such as the material, performance, and brand of the casters.At the same time,Be wary of products with inflated prices or substandard quality.to avoid unnecessary losses.

VII. Practical Testing and Validation

When selecting casters,When conditions permit,It is best to conduct actual testing and verification.By simulating real-world usage scenarios,Observe the performance of the casters in terms of rotational flexibility, load-bearing capacity, and wear resistance.To ensure the selected casters meet actual requirements.

In short,When selecting commonly used casters,Multiple factors must be considered comprehensively.Including the basic structure of casters, usage scenarios and requirements, materials, dimensions and specifications, brands and services, as well as pricing.By scientifically and rationally selecting casters,It can ensure that the mobility efficiency, safety, and stability of the equipment are effectively enhanced.We hope this article provides you with some useful guidance when selecting commonly used casters.

Post time: Sep-13-2025