Casters,As a core component of mobile devices,Its selection is crucial.When selecting casters,Swivel casters and fixed casters are two common types.Each has its own distinct characteristics and applicable scenarios.This article will provide you with essential knowledge on selecting casters.To help everyone better understand and choose between swivel casters and fixed casters.

Steering wheel,As the name suggests,Its direction is fixed.It can only roll in one direction.These casters are typically used on equipment requiring straight-line movement or fixed direction.Such as linear guides, conveyor belts, etc.The advantage of the caster lies in its superior stability and load-bearing capacity.Ensure that the equipment maintains a stable posture and orientation during movement.However,Due to its fixed orientation,Steering wheels tend to be cumbersome when changing direction or turning.Not flexible enough.

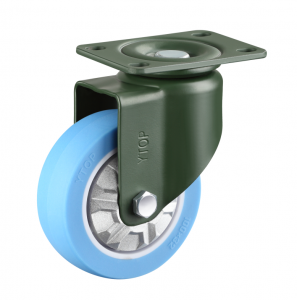

Unlike the caster wheel,Casters can rotate freely 360 degrees.It can easily handle changes in direction and turns.These casters are typically used on equipment that requires frequent changes in direction or needs to maneuver flexibly in confined spaces.Such as shopping carts, medical equipment, office chairs, etc.The advantage of swivel casters lies in their flexibility and convenience.It can significantly enhance the mobility and operational convenience of the equipment.However,Due to its relatively complex structure,Swivel casters may be slightly inferior to fixed casters in terms of load capacity and stability.

When selecting casters,We need to select the appropriate casters based on the specific requirements and usage scenarios of the equipment.If the equipment needs to maintain straight-line movement or a fixed direction,and requires high stability and load-bearing capacity.Then the directional wheel is the better choice.If the equipment needs to frequently change direction or maneuver flexibly in confined spaces,Then swivel casters would be more suitable.

When selecting casters,We also need to pay attention to the following points:

Load-bearing capacity:Select the load capacity of the casters based on the weight of the equipment and the anticipated load.Ensure the casters can stably support the equipment and bear the corresponding weight.

Material Selection:The material of casters significantly impacts their durability and performance.High-quality materials such as high-strength plastics, rubber, or metal offer superior durability and load-bearing capacity.

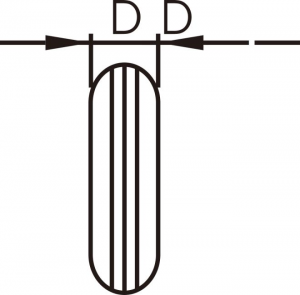

Wheel diameter:The diameter of the wheel affects the mobility and stability of the caster.Generally speaking,The larger the wheel diameter,The smoother the movement,However, it will also increase the overall height and cost.Therefore,When selecting wheel diameter, comprehensively consider the equipment requirements and operating environment.

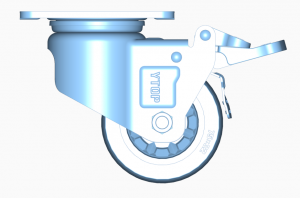

Braking System:For equipment requiring frequent parking,Selecting casters with a braking system offers greater convenience and safety.The braking system effectively locks the casters in place.Prevent accidental slipping or movement of equipment.

In summary,Swivel casters and fixed casters play distinct roles in caster selection.Understand their features and applicable scenarios.and select based on the specific requirements and operating environment of the equipment.will help us select the right casters,Enhance the mobility and operational convenience of equipment.We hope this educational content helps you better understand and select casters.

Post time: Sep-06-2025