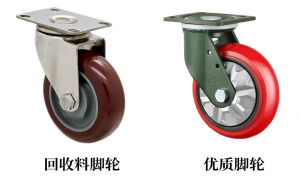

Casters.As an important part of the industrial product Widely used in medical equipment, electronic equipment, supermarket shopping carts, warehousing and logistics and many other fields.The quality of casters directly affects the stability and service life of the equipment.The choice of material is one of the key factors in determining the quality of casters.In this paper, we will look at both recycled materials and high-quality raw materials.Explore their effects and differences on caster performance.

I. Characteristics and impacts of recycled materials

High purity of high-quality raw materials Stable physical properties.This includes strength, hardness and elasticity.In comparison.Recycled materials are recycled one or more times.These materials may contain impurities.whose physical properties may not be as consistent as those of the original material.There may be some degree of performance degradation.

1. Unstable performance

The chemical stability and abrasion resistance of high-quality raw materials are usually better.This means that they are able to maintain performance stability in different environments, the Not easily deteriorated by chemical reaction or wear.Whereas recycled materials are processed and used many times during the their physical and chemical properties are subject to change.The result is that the casters made do not perform well in terms of abrasion resistance, fatigue resistance, and stress cracking resistance.This instability may make the casters susceptible to wear, breakage, etc., during use.Affects the normal operation of the equipment.

2. Corrosion resistance

High-quality raw materials are usually more resistant to corrosion, the Resistant to a wide range of chemicals.The corrosion resistance of recycled materials may be reduced by the recycling of materials.Especially if certain chemicals are used in the recycling process.

3. Security risks

Some recycled materials may contain impurities or hazardous substances.These substances are difficult to remove completely during the caster manufacturing process.May pose a potential threat to the environment in which it is used and to human health.For example.Recycled materials containing heavy metals may precipitate during use.Pollution of the environment and human beings.

4. Poor appearance and texture

Casters made from recycled materials are often inferior in appearance and texture to casters made from high-quality raw materials.Uneven color, rough surface, easy to fade and other problems will affect the overall aesthetics of the caster and the use of experience.

Second, the characteristics and advantages of high-quality raw materials

Compared to recycled materials High-quality raw materials offer significant advantages in the manufacture of casters.

1. Excellent performance

High-quality raw materials such as TPR (thermoplastic elastomer) and PP (polypropylene).Excellent physical and chemical properties.TPR casters are UV-resistant, ozone-resistant, corrosion-resistant, and quiet-running;PP casters, on the other hand, have the advantages of good toughness, good chemical resistance, heat resistance and good resistance to stress cracking.These properties make casters made of high-quality raw materials more stable and reliable in use.Extends the life of the equipment.

2. Environmental safety

High-quality raw materials are mostly environmentally friendly.Non-toxic and odorless.Recyclable.This is in line with the current social requirements for environmental protection and sustainable development.Meanwhile.High-quality raw materials undergo strict quality control during the production process.Ensuring the absence of harmful substances.No threat to human health or environmental safety.

3. Good appearance and texture

Casters made of high-quality raw materials are even better in terms of appearance and texture.Bright color, smooth surface, gentle touch and other characteristics make the caster overall look more beautiful and generous.Enhances the product and user experience.

III. Conclusion

In summary.The difference between recycled materials and high-quality raw materials in the manufacture of casters is mainly reflected in the stability of performance, safety, environmental protection and appearance and texture.While recycled material saves resources to some extent, the However, its performance shortcomings prevent it from fully replacing high-quality raw materials.Therefore.Priority should be given to the use of high quality raw materials in the manufacture of casters.To ensure the quality and safety performance of the product.Meanwhile.Enterprises should also strengthen environmental awareness and technological innovation.Promote the sustainable development of the caster manufacturing industry.

Post time: May-21-2025